There’s something very special about a personalised gift — especially one made from natural materials and crafted by hand. Over the past few weeks, our Cambridgeshire workshop has been busy creating a range of personalised gifts that customers across the UK already love. One item has quickly become a favourite: our personalised solid oak chopping boards.

This month, we wanted to share a behind-the-scenes look at how one of our recent orders came to life. The journey begins with a raw slab of FSC-certified white oak and ends with a finished kitchen keepsake. If you’re curious about our process, searching for personalised wooden gifts in the UK, or simply enjoy a good workshop story, this one is for you.

1. It Starts With Quality: Choosing White Oak

Every board begins with a piece of FSC-certified white oak that is strong, beautifully grained and ideal for everyday cooking. White oak has several qualities that make it perfect for personalised chopping boards. It is naturally moisture-resistant, long-lasting and far less prone to warping than many other timbers. Its natural oils and tannins help reduce bacteria on the surface, making it a safe choice for food preparation. It is also firm enough to stand up to daily use without dulling kitchen knives too quickly.

These qualities, along with its rich grain patterns, are why we choose white oak for our engraved chopping boards. When looked after well, a solid oak board can last for decades and only becomes more characterful with time.

2. Cutting, Shaping and Preparing the Board

Before any engraving can begin, the oak needs to be prepared with care. We cut the timber to the exact size for our medium board (40 cm × 25 cm) and plane it to the customer’s chosen thickness of 4 cm. This gives the board a solid, weighty feel while keeping the proportions balanced.

Once the surface is planed and the edges are cut, the oak is smooth, level and ready for engraving. This early preparation might seem simple, but it’s vital. A clean, even surface allows the engraved design to stand out beautifully and is one of the details that separates handcrafted boards from mass-produced alternatives.

3. Designing the Personalisation

With the oak prepared, the design stage begins.

Using VCarve software, we map out the layout, engraving depth and each of the toolpaths, including the customer’s chosen text and artwork. Once the digital preview looks balanced and the spacing feels right, the file is sent to the CNC machine ready for engraving.

Getting this step right means the engraving looks clean, balanced and intentional once it’s carved into the oak.

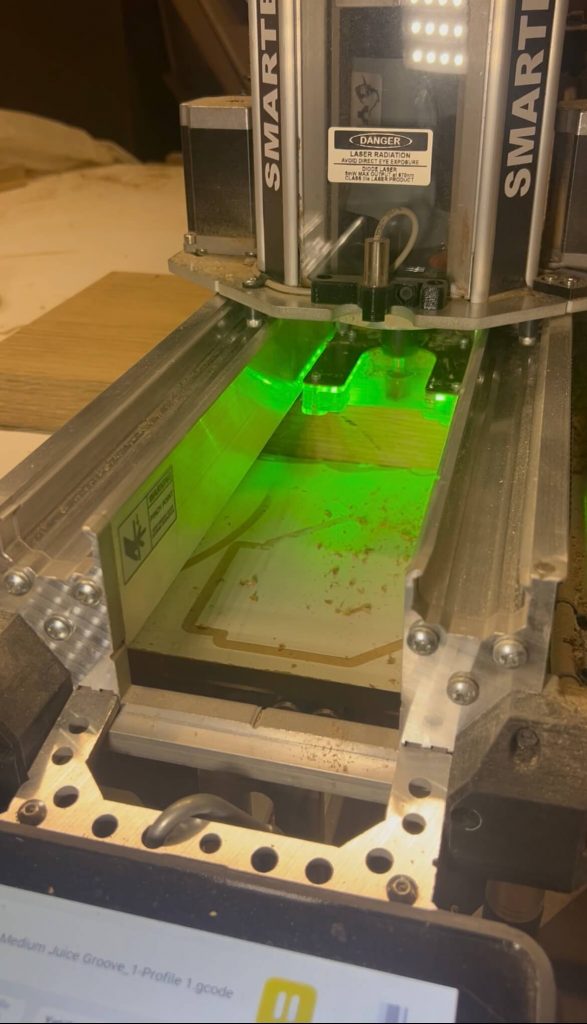

4. CNC Engraving: Watching the Board Come to Life

The board is secured to the CNC bench using strong double-sided tape so it stays perfectly still during engraving. Then the carving begins.

First pass: the juice groove

We run the toolpath that cuts a clean groove around the edge of the board. A juice groove helps catch liquid during food preparation, preventing spills and keeping the worktop tidy. Many customers choose to include one because it adds both practicality and a more defined, finished look.

Second pass: the personalisation

We change the toolbit, load the next toolpath and begin engraving the text and artwork. The CNC machine carves the customer’s chosen design into the board with precision. Even though we see this process often, watching a personal design appear in the oak remains one of the most satisfying parts of the job.

5. Filling the Engraving With Food-Safe Resin

Once the personalised engraving is complete, the next step is to fill the design with a clear, food-safe resin. This gives the engraving a smooth, sealed finish and ensures that food, moisture and oils can’t work their way into the carved areas over time. It also keeps the lettering and artwork looking crisp, even with daily use.

We pour the resin carefully into the engraved sections and leave it to cure for at least 24 hours. Once it has fully set, we return the board to the CNC machine to shave away the thin top layer of excess resin. This ensures the resin sits perfectly flush with the surface of the oak before sanding begins.

Removing the excess mechanically at this stage is important. It means we don’t over-sand the design later on and ensures every detail, from fine lettering to small illustrations, remains sharp and precise in the finished board.

6. Sanding… and a Little More Sanding

Fresh CNC cuts have sharp edges, so the board goes through a lot of sanding. Most of the smoothing is carried out using our belt and orbital sanders to keep the surface even, but the finer details — like the juice groove and engraved areas — are finished by hand where needed. The edges are softened using a router so the board feels comfortable to lift, carry and use.

This step is where the board starts to feel “finished.” The oak becomes smoother, the engraving becomes clean to the touch, and the whole piece begins to take on the feel of a true handmade kitchen gift.

7. Finishing With Food-Safe Oil

For the final stage, we treat the oak with a food-grade chopping board oil. The grain deepens in colour, the engraving becomes richer and the oak takes on the warm, natural sheen that customers love.

Every order includes a care card with simple tips for cleaning, oiling and maintaining the board so it lasts for years.

The customer who ordered this board was thrilled with the result and left us this lovely review:

“Very happy with my personalised chopping board. Very thick, heavy and I was updated at every stage. Great customer service, excellent delivery and very well packaged. Definitely recommend.”

Reviews like this mean the world to us. There’s something wonderful about knowing our work will be used and enjoyed in family kitchens around the UK.

Thinking About a Personalised Wooden Gift?

If this project has inspired you, you can explore our full range of personalised chopping boards and serving boards.

Each board is:

- crafted from FSC-certified oak

- fully customisable

- engraved to order

- made to last for decades

- ready to dispatch in 3-5 working days (5-7 for end grain boards)

Whether you’re searching for a thoughtful Christmas gift, a wedding present or a personalised kitchen centrepiece, our oak boards are among the most loved personalised gifts UK customers choose again and again.

And if you have a unique idea in mind, we’d be happy to bring it to life.

Black Friday Offer — Starting Monday 24th November

To celebrate the season, we’re running a Black Friday offer across all of our products:

⭐ 20% off everything

⭐ Free UK shipping

⭐ Ends Sunday 30th November

It’s the perfect time to order a personalised wooden gift and have it handcrafted in time for Christmas. Visit our shop page for more details!

Leave a Reply